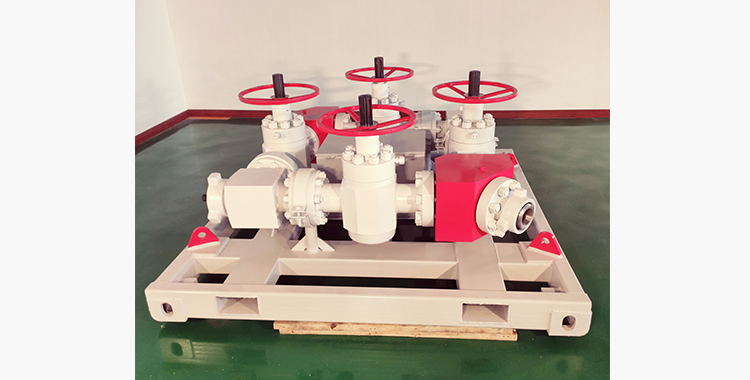

Choke Manifold

The Choke Manifold consists of choke valves, gate valves, pipes, fittings, pressure gauges and other components. It is a necessary device of controlling the well kick and executing the pressure control on oil & gas in the process of well drilling and producing. When BOP is closed, it can control the final pressure from casing by adjusting the opening & closing of the choke valve, which avoid pollution of oil-layer and improve the speed of drilling and control blowout effectively. Also in well testing and producing, choke manifold is used to control the crude oil and gas flow rate and pressure to achieve a proper yield to avoid following equipment's overpressure and overloading by changing the choke beans.

Features

- Control pressure to prevent overflow and overloading.

- Reduce wellhead casing pressure by relief function of choke valve.

- Full-bore and two-way metal seal

- Choke bean features hard alloy inside, delivering high resistance to abrasion and corrosion.

- Configuration type: Four Valves, Five Valves, Eight Valves or riser manifold

- Control type: manual, hydraulic, RTU

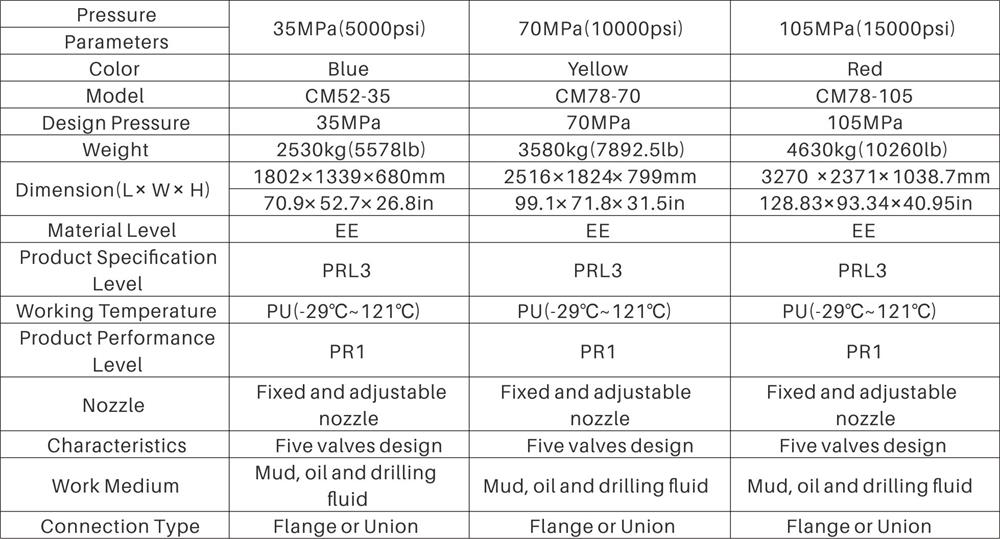

Technical Parameters

- Design pressure: 2000-20000 psi (21-135 MPa)

- Diameter: 2-4 in. (DN50-100)

- Material Class: AA-HH

- Standards: API 6A, API 16C, NACE MR0175, DNV