Steam Heat Exchanger

Incomplete separation of high viscosity oils can seriously affect well testing. Low temperature is the key cause of high viscosity, leading to increased non-productive time.Our steam heat exchangers elegantly solve this problem by rapidly heating the well effluents before they are fed into a 3-phase well test separator.Designed as a compact skid-mounted unit, our steam heat exchanger requires minimal space and can be installed quickly.

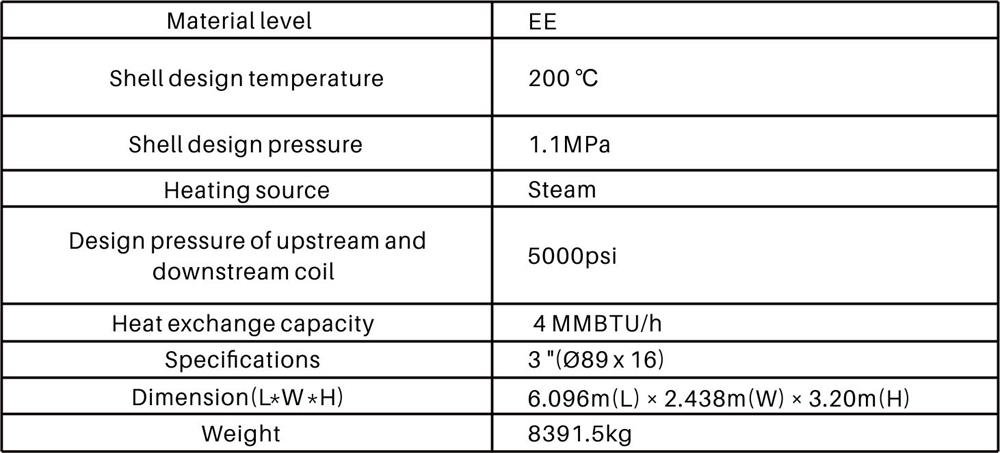

Technical Parameters

- Advanced insulation of the vessel for maximum efficiency

- Preheating of effluent

- Automatic temperature control

- Skid-mounted for impact proof easy installation and transportation

Pressure Vessel Standards

We can build our pressure vessels according to the following standards:

- ASME BPVC Section VIII-1 Rules for Construction of Pressure Vessels

- TEMA Class B Pressure vessels for chemical process services

- TEMA Class C Pressure vessels for general commercial applications

- TEMA Class R Pressure vessels for the severe requirements of petroleum processing

- API 650 Welded Steel Tanks for Oil Storage

- API 620 Design and Construction of Large Welded Low Pressure Storage Tanks