Test Separator

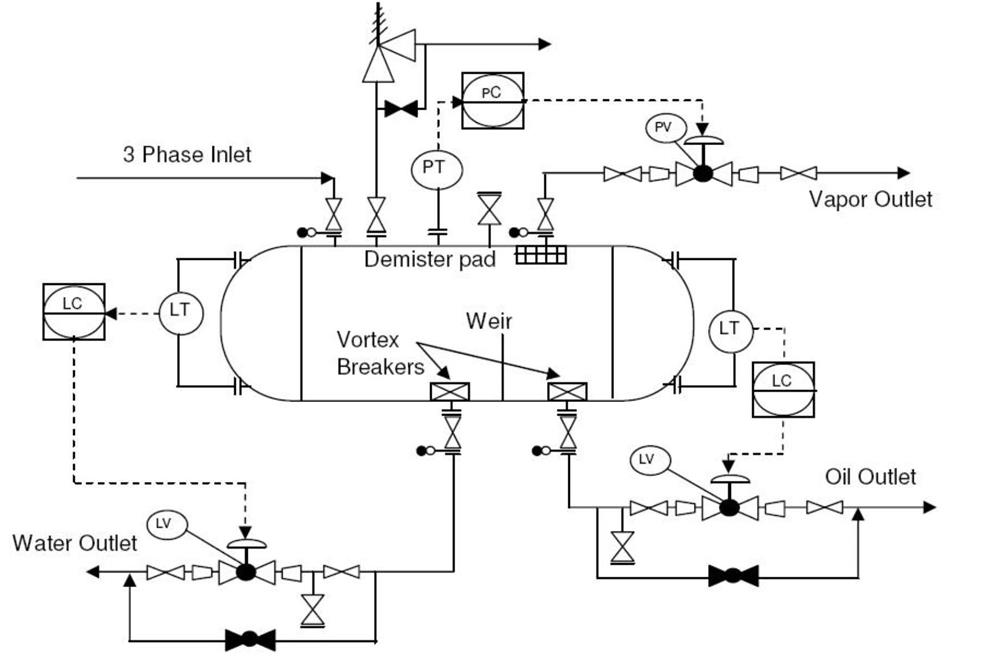

Test separator is designed to separate well fluids into two (gas-liquid) or three phase (gas, oil, water). Another important function of test separator is to provide reliable data of each phase. Data of each phase, such as pressure, temperature, flow is collected, analyzed, and recorded. Test separator also has multiple sample ports to allow collect gas, oil and water. Then samples are tested in special laboratory instruments, which are usually installed in laboratory and office cabin.

Test separator can be supplied as special closed modular unit with heating system allowing operators to work under harsh working environment. Test separator is supplied as modular structure for standalone use or trailer mounted which increases mobilization efficiency.

Test separator consists of separator vessel with high-efficiency internals, manual valves, pneumatic control valves, check valves, relief valves, flow meters, pressure and temperature transmitters, gauges, and other necessary components for convenient and effective well testing.

Technical Parameters

- Gas flow rate 25-50 X 104 NM3/D (or more)

- Liquid flow rate: 50-300 m3/d (or more)

- Working media: Natural Gas, Crude Oil, Chemical Substances, other liquids and gases.

- Max Design pressure: 9.8MPa (1400psi) (2160 psi is also available)

- Normal operate pressure Max: <7.5MPa (1088psi)

- Safety valve set pressure : 7.5MPa (HP) (1088psi)

- Rupture Disc set pressure : 9.4MPa (1363 psi)

- Gas Flow measure precision : ±1%

- Overall dimensions (L*W*H): 7.3 m*2.2 m*2.5 m

- Power supply: 220V AC,10A

- Monitoring mode: IPC control

- Inlet & outlet connection type : Hammer Union

- Structure: Skid-mounted, trailer-mounted, or integrated with indirect water bath heater

- Certification: ASME, API, PED/CE, ISO, NACE MR0175, DNV

Working Process